The visibility gap

Your ERP system shows one reality. Your production floor operates in another.

Orders sit in your system marked as "in progress," while supervisors try to determine which line is running what. Production targets look achievable in planning meetings, but the shop floor reveals a different story. When problems arise, you discover them hours or days too late—after scrap accumulates, missed deadlines, or customer complaints.

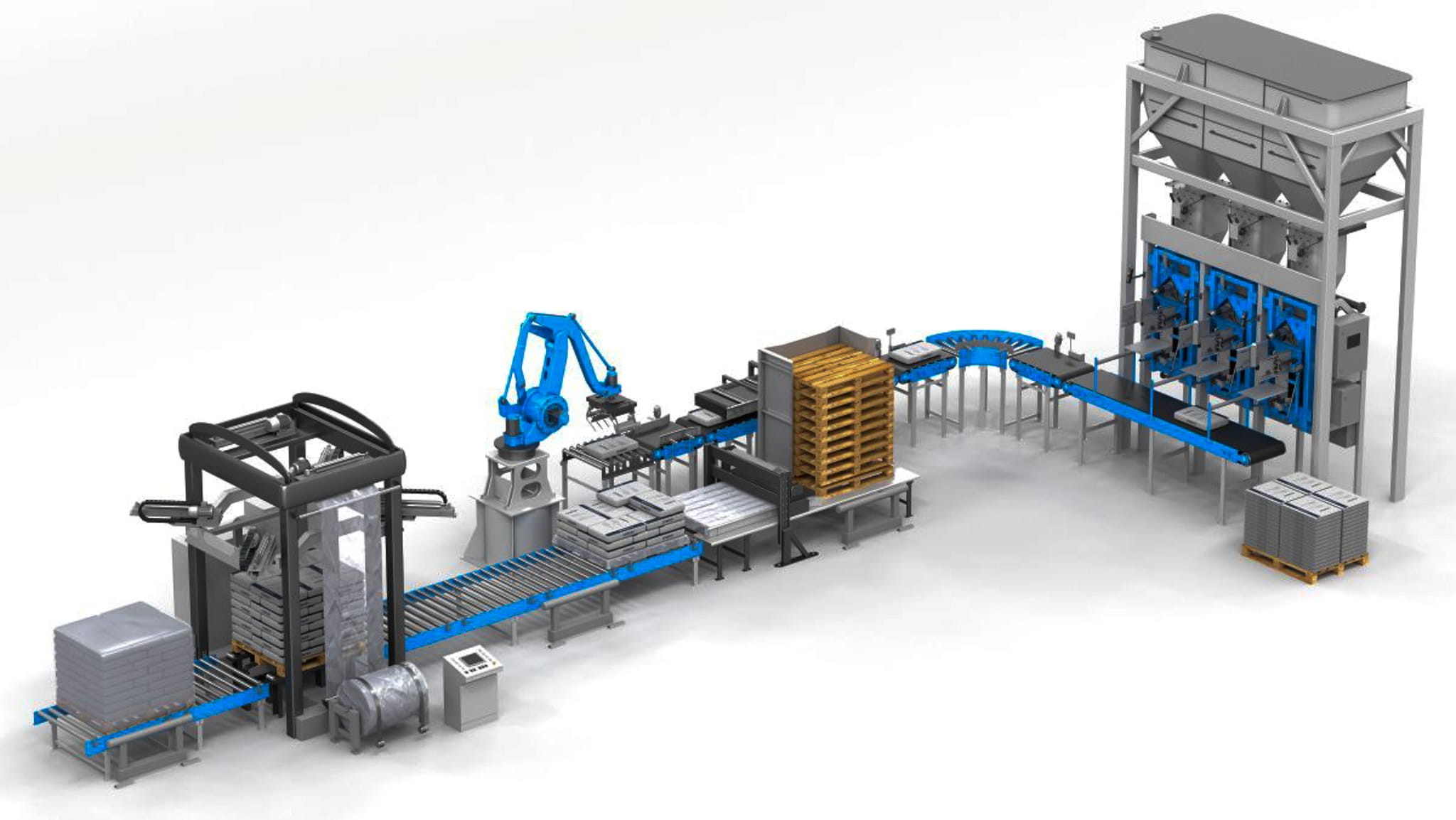

At ABISS 2025, we demonstrated a working solution: a complete IT-OT integration that connects ERP data to real production-floor activity, delivering real-time insights into production status, equipment performance, and quality metrics. It is a functioning system that runs on real industrial hardware.

What we demonstrated at ABISS 2025

The business layer: ERP integration

We integrated business data from Dynamics ERP (stored in Dataverse) with production floor machines. The system creates work orders for a virtual factory that paints containers, canisters, and drums in various colors.

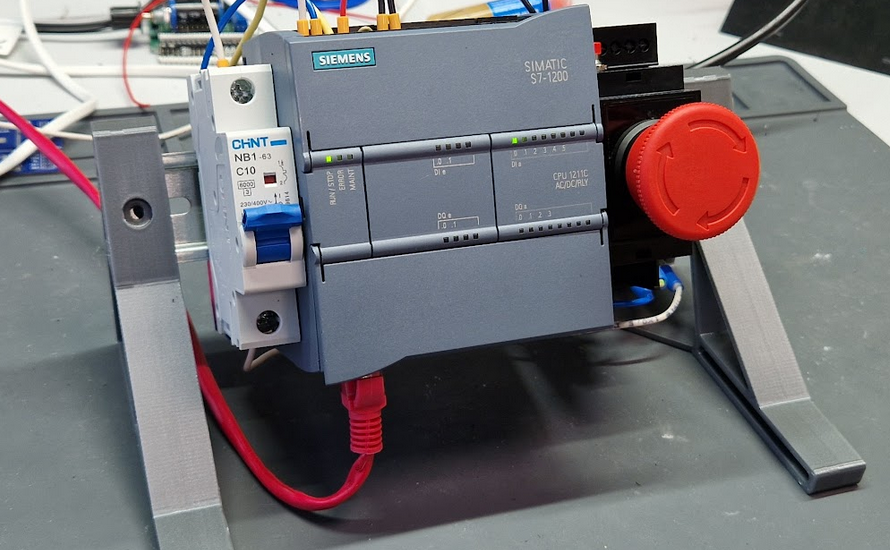

The production layer: Real control hardware

The production line is virtual, visualized as a 3D digital twin that mirrors the physical behavior and real-time state of an actual production line. The control system is real—an actual Siemens PLC physically installed for the demo.

The intelligence layer: Smart scheduling

We built a work order scheduler (WOS) to manage line loading. When the line becomes available, the scheduler automatically loads the next work order from its optimized queue.

Paint lines present a specific challenge. Changing colors—which requires stopping production, flushing equipment, and cleaning spray systems—is a costly process.

The WOS looks ahead. It examines the order queue and intelligently sequences jobs to minimize the number of changeovers. Three orders for blue items and two for red? The scheduler groups similar colors together. Downtime decreases, and throughput increases.

This optimization is automated, based on real production constraints and current line status. Such operational intelligence becomes possible when IT and OT systems communicate seamlessly.

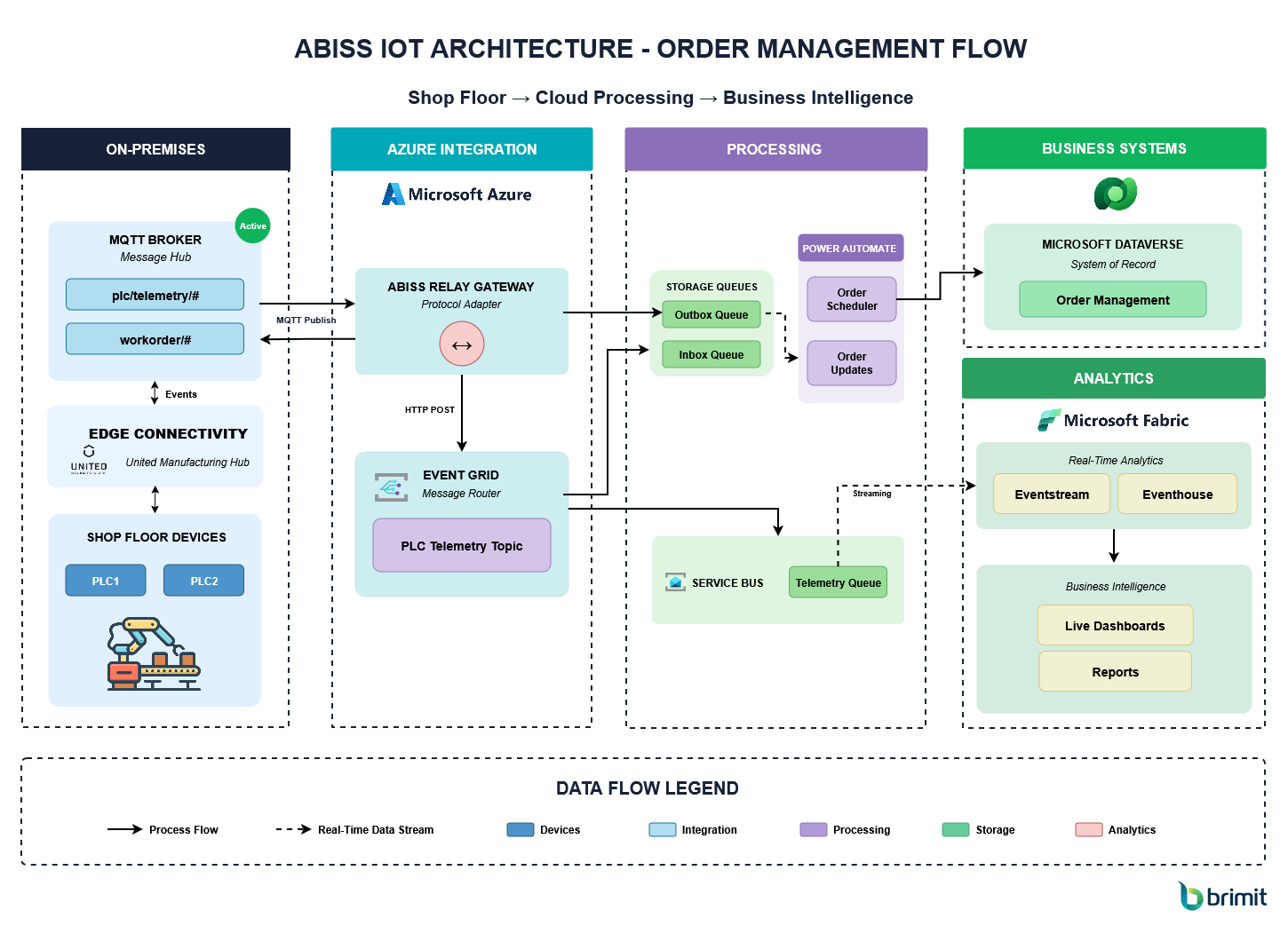

The technology behind the demo

Unified Namespace architecture

The foundation is Unified Namespace (UNS). This architectural approach structures how IT and OT data converge and flow. Instead of point-to-point integrations between every system (which become maintenance nightmares), UNS creates a standardized data structure. All systems can publish and subscribe to it.

Bidirectional data flow

The demo updates work orders in the ERP system with actual production data. As the line processes orders, status changes, completion rates, and performance metrics are returned. This bidirectional data flow is uncommon in manufacturing operations, but it's essential for genuine visibility.

Flexible visualization options

We built a simplified MES dashboard using Power Tools. It tracks overall equipment effectiveness (OEE) and other key production metrics.

The specific tools are not the constraint. The same integration will work with Grafana, Superset, Metabase, or any other analytics platform. The value comes from the integration architecture, not from specific software vendors.

Accessible technology foundation

The core integration platform doesn't require expensive enterprise licenses. In our setup, we used United Manufacturing Hub (UMH), an open-source Industrial IoT platform specifically designed for manufacturing environments. It handles the complexities of industrial protocols, data normalization, and bidirectional communication between business systems and production equipment.

This eliminates expensive licensing fees while providing enterprise-grade integration capabilities. The technology costs align with the budgets of mid-sized manufacturers, not just enterprise-level IT departments.

Real business value: Who benefits and how

Value for production teams

For production supervisors and operators, the system provides immediate operational intelligence. When a line stops, they see why—immediately.

Is it waiting for materials? Did equipment malfunction? Is a changeover in progress? Is there a quality hold?

The information appears instantly on floor displays. No time is wasted on investigation.

Value for business leadership

For business management, the system delivers truth. Real-time visibility into whether production performance matches business expectations: current order status, actual throughput rates, equipment utilization—all updated continuously, not reconstructed from end-of-shift reports.

Choosing the right data speed

Do you always need real-time data? The honest answer is no.

Many manufacturing decisions work perfectly well with near-real-time data (updated every few minutes) or even batch updates (hourly or daily). We wrote an entire playbook on this topic. RELATED ARTICLE Do You Really Need Real-Time Analytics?

The key insight: Match data speed to decision speed. If your team needs to respond to problems within minutes, real-time data will help. If decisions occur on daily or weekly cycles, batch processing often suffices. The architecture we demonstrated supports both approaches. You choose the data latency that matches your operational needs and budget.

Tangible improvements

Integrated IT-OT systems enable:

- Faster problem response: Issues get flagged when they occur; they're not discovered hours later

- Better resource utilization: Intelligent scheduling reduces changeover time and idle capacity

- Accurate performance tracking: Real production data eliminates guesswork from planning

- Improved order visibility: Sales teams and customers get accurate status updates automatically

Understand where to start with data and AI

Why this matters now: The competitive imperative

The competitive shift

IT-OT integration has shifted from an optional technology upgrade to a competitive requirement. Manufacturers who win contracts can provide accurate delivery commitments, respond quickly to changes, and demonstrate reliable quality through data.

Production facilities that operate with real visibility can underbid competitors who pad schedules to compensate for uncertainty.

The accessibility myth

A persistent myth prevents many mid-sized manufacturers from pursuing this capability: the belief that IT-OT integration is only accessible to large enterprises with massive IT budgets and dedicated teams.

The barrier to entry is no longer technology capability or cost. It's the misconception that integration requires a massive, all-or-nothing commitment.

Start small, prove value, scale

Begin with one connection

The most successful IT-OT integrations begin with small iterations. A single production line or work cell connected to the ERP system establishes a bidirectional data flow, where orders are sent to the production floor and then returned to the back office.

This first integration reveals how IT-OT convergence works in your specific environment, with your specific systems, operated by your specific team.

Prove value quickly

Within weeks, not months, you have working visibility into one part of your operation. You can measure the impact. How much time does automatic status updating save? How many scheduling mistakes get prevented? What's the actual ROI?

With real numbers from the first integration, scaling decisions become data-driven rather than speculative. You know what works. You know what the team needs to learn. You know what results to expect from broader deployment.

Scale based on results

After proving the value of IT-OT convergence on one line, expand to similar processes. Add more sophisticated capabilities—predictive analytics, automated scheduling, quality control integration—but only after foundational integrations have been shown to work reliably. Each increment builds on previous success.

This approach avoids a common failure pattern: Companies invest heavily in comprehensive platforms, spend months on implementation, and end up with expensive systems that their teams struggle to use.

Integration that solves specific problems, works with existing equipment, and scales at a pace the organization can absorb doesn't require out-of-the-box digital transformation platforms with enterprise-grade price tags.

Getting started: Your first integration

Assess existing systems

Understanding current capabilities is the foundation of planning IT-OT integration. What ERP platform runs the business? What equipment controls production lines—PLCs, SCADA systems, or standalone controllers?

How do these systems currently communicate (if at all)? Where is production data kept? In spreadsheets or operator logs? Or is it not captured at all?

Choose a pilot

Select one production line or process where improved visibility would deliver clear, measurable value. Strong candidates include:

- Bottleneck operations where better scheduling would increase throughput

- High-variability processes where real-time monitoring would catch problems faster

- Customer-critical production processes where accurate status updates would improve service

Start simple

The first integration doesn't need sophisticated analytics or AI-powered optimization. Basic connectivity that shows real production status already provides significant value. Build complexity only after the foundation is working reliably.

From conference demo to your shop floor

Accessible technology, real implementation

The system we demonstrated at ABISS 2025 represents a working integration built using platforms, protocols, and equipment available today. The same architecture can connect ERP systems to production floors—it can be easily adapted to the specific systems, processes, and requirements of any facility.

The demonstration proves that integration is accessible, implementable, and valuable for manufacturers of any size.

The path forward

Starting small eliminates the need for expensive platform subscriptions or multi-year transformation projects. One connection. One line. Prove value before scaling.

A focused integration that solves specific operational challenges and delivers measurable results lays the foundation for broader capabilities.

The competitive reality

Production facilities that operate with genuine IT-OT visibility are winning business from those that operate on assumptions and delayed information. The question is not whether to pursue this capability but how quickly to implement it.

This is how mid-sized manufacturers achieve IT-OT integration without enterprise-scale budgets or risks. It's how companies move from watching conference demonstrations to operating with real production visibility.